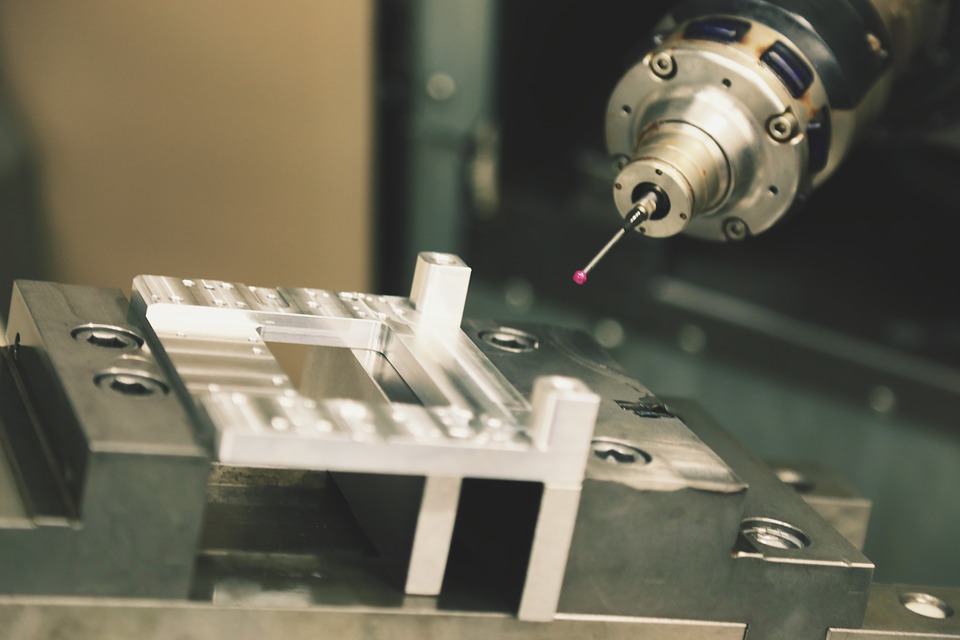

Small Batch CNC Machining

CNC (Computer Numeric Control) machines do have a number of applications in manufacturing and in businesses. These are normally used anywhere due to the automated needlework of machines. These machines are able to work by making the embroidery designs to the robotic arms that are mainly used in automobile manufacturing.

Due to this precision, it is possible that the best applications are the CNC machining services that are able to provide precision parts regardless of the volume. These CNC machining services are able to produce anything from the bolts that work in the oil rigs to the engine components. These could also be able of creating custom parts that are helpful from the prototyping stage to the last phase of production.

There are few industries that are making use of the various precision equipment’s that is why CNC is very ideal in the market world today. However, the fact is that not all these services are same, and thus some of them will not be able to create the capabilities of manufacturing the parts that clients need, thus making you waste a lot of time trying to find the right company that contracts to make the machine components that you need. Therefore, gaining the right knowledge regarding machining services is very relevant.

One thing that you need to make a decision on is the kind of components that you need manufacturing. these services have various equipment they use in machining your parts, but the fact is that not all of them are able to manufacture the more complex parts at high volumes within shorter times. By determining the kinds of parts that you will need will give you the chance of narrowing down your choices at the beginning of the search.

The other key important aspect you will need deciding on is the volume hat you need to be manufactured. If you need the small-batch components, then the smaller firms that specialize in the CNC machining services will have to be tricky to ensure they are capable of manufacturing parts that you need. Likewise, if you are true of the high volume parts then the large machining services will definitely work for you better. There are some services that will be able to produce high volume but can also limit the contracts based on the batch basis.

One of the most efficient ways you can utilize when searching for machining services is by limiting yourself to those around you. This will make it easier for you to cut shipping costs, picking up orders, and making the right inquiries. Apart from their capabilities as machining services, you can also be able to do quality control inspection. You can ascertain whether they are able to meet accreditation by the standard regulation organizations. One of the ways in which you can be able to determine the high standard of products.

Designing Parts for Small Batch CNC Machining

Combined with 3D CADCAM, CNC Machining has been able to revolutionize workshop practices. this has opened great world possibilities for the designers that design that machined components that are intended in producing medium-sized or the small batches.

However, there are some things that have really changed and also we have some constraints from what most of the designers view. The ultimate constraint on the designers has always been the costs. Almost anything can be made when the cost is not a constraint. all the designers need to know which features on the components are easy and cheap and the ones that are more costly and difficult. However, this is not that simple unless you have the right experience when it comes to the manufacturing of parts by the use of modern processes.

What are the advantages of small batch CNC Machining?

When you need to change the machining object on the CNC machines, what is only needed is rewriting the machining programs. There is no need of updating tools, melds, and fixtures. This will save a lot of process equipment costs. besides, due to the high precision, there will be high productivity, reduced production costs, reduced scrap rates, and stable qualities. Usually, the control of information for the automated machining on the CNC machine tools is on the machining programs. Therefore, even when the machining objects are changed in addition to the corresponding tools change, as long as the machining programs of the part are rewritten and input, the new parts will automatically be machines without having to, take complicated adjustments of the machine tools. This thus shortens the production process whereby the preparation cycle will provide shortcuts for the new product developments, product modification, and improvement. The CNC machining tools are always that rigid and thus they are able to enable strong cutting and the fast stroke can be used also for idle travel time and saving maneuver. The CNC machine tools can spindle and feed speed range that is large thus you can make a choice on the most reasonable cutting that you need. More so, the machining parts on the small-batch CNC machine tools will require no adjustments and low fixtures. They also have high repeatability that will shorten the time used in the production, thus saving on the inspection and measure times. Therefore, the small-batch CNC machines tools are that much product that the ordinary machines. If this machining is put underuse, the rotary table automatically changes, the automatic tools change and thus the multiple machining processes can be realized on one machine tool. Also, the cycle time of the semi-finished products can be shortened, improving the production efficiency CNC machine tools are usually used in manufacturing and processing. These machining programs are usually programmed according to the debugging program, the drawings and the clamping parts are then processed. These machining processes are thus observed and the parts are then loaded and unloaded. Additionally, the need for doing the repetitive manual operations declines, labor tension and intensity declines, and the labor conditions are improved similarly. CNC machine tools are highly combined with mechatronic products. This usually entails the automated system control and precision machinery. thus, the transmission system of the structure of the machine tools and the machine tool have thermal stability and are highly rigid. When this transmission structure is redesigned, the measure of error reduction is taken and highly compensated using the numerical control devices, the machines that have higher machining precision. The small-batch CNC machine tools are thus not limited by the complexity of the parts, something that is not comparable to the ordinary machine tools. And since the CNC machine tools are usually automated processes according to the programmed programs, human errors are highly eliminated. More so, the consistency when it comes to the processing of the same small batches is improved and faster, the product qualification rate is high and the quality is stable. For these parts that need the multiple procedures, the onetime clamping is ideal in the performance of continuous processes improving the machining accuracy of the parts and reducing the clamping error.

CNC small batch machining has good economic benefits

CNC small batch machining has strong adaptability to the processing objects

Small batch CNC machining enhances high productivity

Small batch CNC machining helps in the labour reduction and also improves the working conditions

Small batch CNC machining is highly accurate

When in need of the best Small Batch CNC machining, it is always good to look for service providers who have various services to offer that will be able to cater for your requirements and manufacturing needs. Customer service, skills, and efficiency are some of the key things you can consider when making a choice of the best company. USA Contract Manufacturing Specialists are of great help when it comes to dealing with CNC machining. Contact them for the best deals ever within your budget.

If you need any of our services, feel free to get to us and we will give you a free quotation. The company guarantees you that you will get the value for your money in any service that you hire from us. We have the right technicians and machines to help you out on any metal project that you could be having at your individual or business needs.